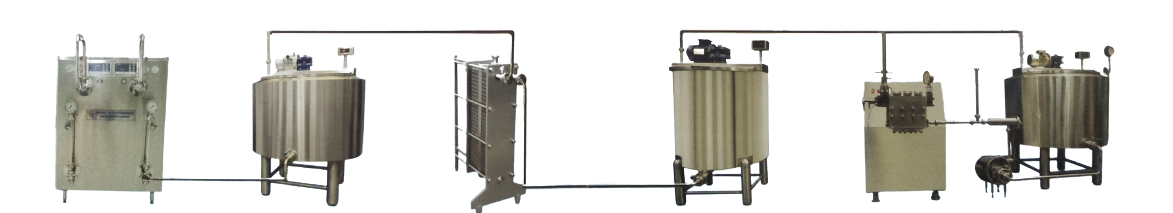

Harvest offers a turnkey solution for Ice Cream Plant/Frozen dessert/Non-Dairy Whipping Cream Plant. Right from reception of Raw materials , mix preparation to processing, freezing, packing & cold storage. We provide entire solutions for processing plants ranging from 200 LPD – 50000 LPD..

Pasteurizing Tank

Pasteurizing tank is used to mix and heat all the raw materials to produce basic ice-cream mix.

| Model | HTPT 200 | HTPT 300 | HTPT 500 |

|---|---|---|---|

| Capacity in ltr | 200 | 300 | 500 |

| Gear Motor HP | 0.5 | 1 | 1 |

| Water Jacket | 100 ltr | 100 ltr | 100 ltr |

| Shape | Round | Round | Round |

Features

- Extra rich hyginic constraction & easy to clean

- All products contact parts made of SS 304 / 316

- Water Jacket construction for even heating

- Low power consumption due to proper glass wool insulation in tank

- Avilable in steam, heater and LPG Geyscer

Homogenizer

Homogenizer is used to process the ice-cream mix processed in the pasteurizer tank. In homogenization product is forced inside the valve area at high pressure and low velocity. As the product enters the adjustable, micron clearance area between the homogenizer valve and seat. There will be a rapid increase in velocity with a corresponding decrease in pressure. Intense energy release causes turbulence and localized pressure differences, which will be used to tear apart the particles. This improves the quality and stability of the product.

| Model | HTHM 200 | HTHM 300 | HTHM 500 |

|---|---|---|---|

| Capacity ltr/ hr | 200 | 300 | 500 |

| Motor, HP | 2 | 3 | 5 |

| Max Working Pressure, bar | 175 | 175 | 175 |

| No. of Pistons | 3 | 3 | 3 |

Features

- Heavy duty plastic coated frame with SS 304

- Two stage Homogenization

- Low SPM plunger speed

- Pressure adjustment by hand/hydraulic

- Stellite stage valves for both stages

- Adjustable ball feet arrangements

- SS diaphragm type sanitary design pressure gauge

- High strength steel eccentric shaft and connecting rod assembly

- Splash lubrucating system

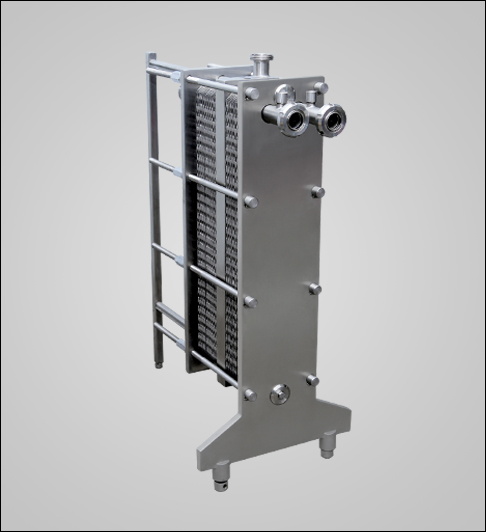

Plate Heat Exchangers

Plate heat exchangers brings down the temperature of the basic mix to 4- 10°C from 82°C.

| Model | HTPHE 200 | HTPHE 300 | HTPHE 500 |

|---|---|---|---|

| Capacity ltr/ hr | 200 | 300 | 500 |

| Motor, HP | 18 | 24 | 32 |

| Stages | Single stage / Double Stage | ||

Features

- Heat transfer

- No Space constraint

- Expansion provision

- Heat recovery

- Liquid hold – up is minimal

- Reduced fouling

- Competitive price

- Increase in turblence

- Wide range of duties

Ageing Tank

It is used to store the basic mix at 4°C & makes it ready for process.

| Model | HTAT 200 | HTAT 300 | HTAT 500 |

|---|---|---|---|

| Capacity ltr/ hr | 200 | 300 | 500 |

| Gear Motor HP | 18 | 24 | 32 |

| Glycol Jacket | 100 ltr | 150 ltr | 200 ltr |

| Shape | Round | Round | Round |

| Refrigertor | R-22 | R-22 | R-22 |

| Compressor | 1.5 ton | 2.0 ton | 2.5 ton |

Features

- Extremely Compact Mechanical Design

- Round mix tank for proper mixing of ice cream mix

- All product contact parts made from SS 304 / 316

- Low power consumption due to effecient refrigeration

- system, Puf insulation and proper electrical system

- Top drive starter with easily removable for complete cleaning

Continuous Ice cream freezer

Continuous freezer is used to convert the flavoured mix to real ice cream by fusing air and continuous churning using refrigerant.

| Model | HTCF 200 | HTCF 300 | HTCF 300 | HTCF 400 |

|---|---|---|---|---|

| Capacity ltr/ hr | 100 | 200 | 300 | 400 |

| Motor, Hp | 1 | 2 | 5 | 5 |

| Max Working Pressure, bar | 0.5 | 1 | 2 | 2 |

| Refrigertor | R-404A | R-404A | R-404A | R-404A |

Features

- Fully-automatic or semi-automatic controls.

- Stainless steel 304 frame and covering panels.

- Advanced dasher construction.

- Mix and discharge gear pumps in CIP design.

- High efficiency air filtering and sterilising system.

- The control unit adopts advanced touch-screen control.

- Maintenance can be done by a domestic refrigerator technician.

- The machine is suitable for large scale continuous hard ice cream production in ice cream industry.

- The dasher system is designed to work continuously, avoiding motor restart between each ice cream extraction.

- Interlock and safety controls for single phase, over load, low and high refrigerant pressures.

- The utilization of a pre-aeration mixer provides additional mechanical working of the fat globules to yield an improved product texture that is rich creamy. This process can improve the texture of lower fat content product to have the same “mouth-feel” as a premium product with a high fat content.